About

Quality Control

At our company, quality is paramount. We adhere to strict quality control measures throughout the fabrication process to ensure that each piece meets the highest standards. Our commitment to excellence extends beyond the final product, as we prioritize timely delivery and exceptional customer service.

When you choose our custom fabrication services, 3D Printing, or other engineering services, you can expect:

Personalized attention and collaboration with our skilled team.

Cutting-edge CNC machining technology for precise fabrication.

Utilization of a wide range of materials to suit your needs.

Attention to detail and adherence to stringent quality control.

On-time delivery and outstanding customer support.

Our Commitment

Precision Concepts is located in Forest Lake MN and has customers that span the United States.

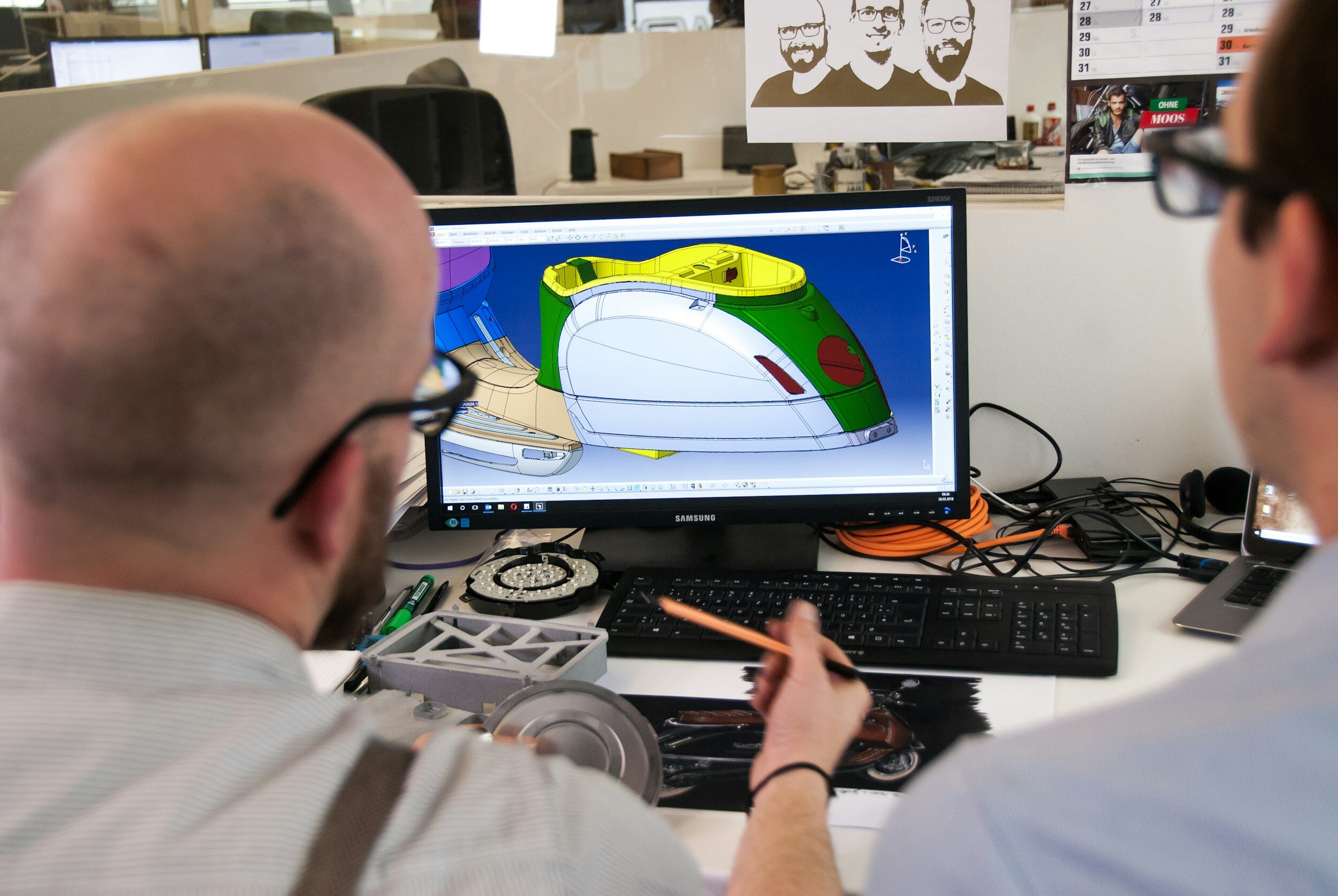

Our team of experienced engineers and designers work closely with you to understand your needs, offering guidance and expertise throughout the fabrication process. We employ advanced CAD/CAM software to ensure precise measurements and flawless designs, guaranteeing a perfect fit for your intended application.

Equipped with cutting-edge CNC machines, we possess the ability to handle a wide range of materials, including steel, aluminum, stainless steel, brass, and more. Our skilled machinists utilize these tools to meticulously shape and form the metal, creating precise cuts, bends, welds, and finishes. The result is a finished product that exceeds expectations in terms of both aesthetics and functionality.

Our Flexibility

We cater to diverse industries, including automotive, architecture, industrial equipment, and beyond. Whether you require prototyping, small-scale production, or large-scale manufacturing, we have the capacity and expertise to handle your project efficiently and effectively.

Experience the perfect blend of artistry and precision with our custom metal fabrication service. Contact us today to discuss your project and let us turn your metal fabrication dreams into reality.

How it all started

Precision Concepts began as a small job shop out back in a garage. The set up was humble, comprised of just a few machines. As word of the company's quality work spread, along with their commitment to customer satisfaction, the business quickly outgrew the confines of the garage. This growth prompted a bold decision, to expand and invest in advanced machinery to meet the changing needs of their customers. One such addition was the acquisition of a KIWA CNC Machining Center, fondly nicknamed "Old Faithful" due to its reliability and consistent performance.

As Precision Concepts continued to thrive it was understood the need to offer more comprehensive services. With this in mind, capabilities were expanded, introducing both CNC Milling and CNC Turning. This significant enhancement enabled a wider array of customer needs and cater to more complex projects.

In this dynamic and ever-evolving industry, Precision Concepts has consistently proven their commitment to adapt and grow, ensuring that they remain at the forefront.